OUR TECHNOLOGY

Metal hydride hydrogen storage solution

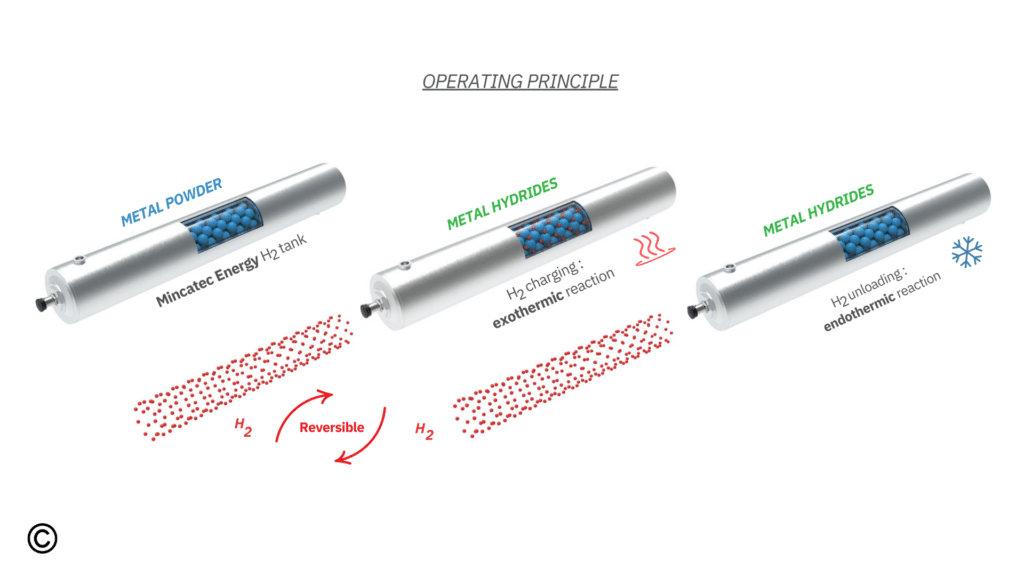

Metal Hydrides: The Key to Sustainable and Infinite Hydrogen Storage

Metal hydrides store hydrogen into metal powder thanks to metal bounds. The absorption of hydrogen by hydrides is an exothermic process ; it releases heat. The desorption of hydrogen from hydrides is an endothermic process as it create cold. Therefore, it is important to focus on thermal management. These processes are reversible, allowing us to reuse the metal powder for hydrogen storage almost indefinitely.

MHYT - H2 industrial tank

Characteristics and Data

H2 storage capacity: 1 kg

Tank mass: 72 kg

Pack volume: Ext – 30 L / Int – 18 L

Pack dimensions: L = 1801 / d = 127 mm

Operating temperature: from -16°C to 80°C

Storage temperature: from -40°C to 100°C

Ab/Sorption: < 4 kWh/kg_H2

Equilibrium pressure: 10 bar at 20°C

Loading pressure: maxi 50 bar

Loading time with cooling: < 10 mn

Tank material: aluminium alloy

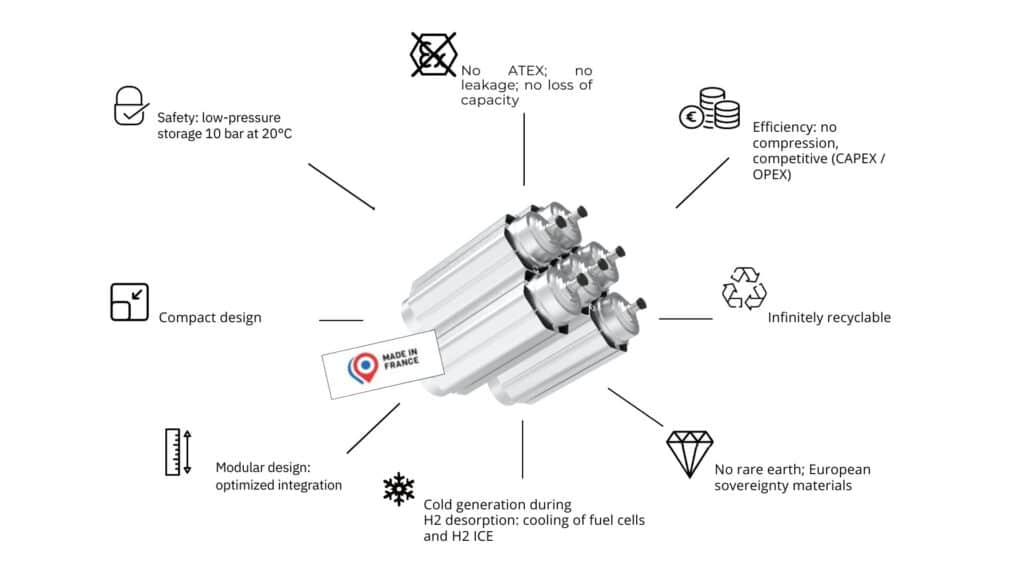

Innovative solution for efficient cogeneration

The innovative aspect of our technology lies in the design and implementation of compact and modular hydrogen storage tanks using low-pressure metal hydrides, enabling cogeneration through the utilization of the thermal energy generated by this tank for other purposes.

A modular solution for all your projects.

Our solid hydrogen storage solution integrates into all your projects:

For residential stationary applications through a hybrid self-consumption system. It allows for the storage of excess renewable energy and the production of electricity for inter-seasonal use (cogeneration principle).

For industrial applications with a containerized solution for storing non-controllable intermittent energies such as wind or solar.

For mobility applications, utilizing hydrogen as an energy carrier.

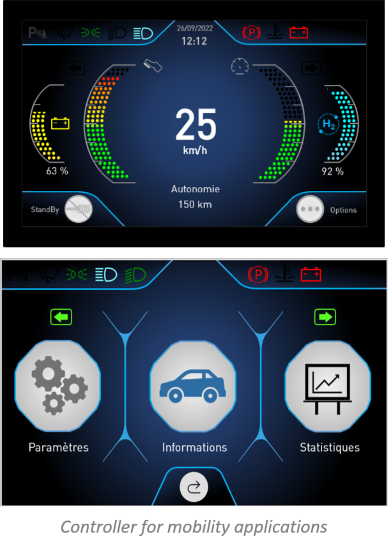

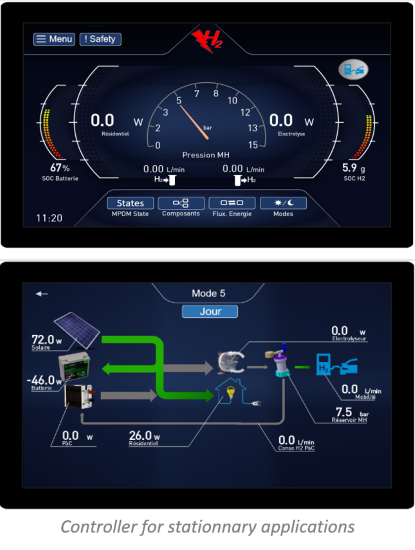

Energy Management System

MINCATEC Energy has developed its own control and monitoring system. This control and monitoring system has two variations: one for stationary applications and one for mobility applications. It offers the following functionalities:

- Optimization of energy inputs from the multi-source system

- Control and continuous monitoring of data from each subsystem

- Customizable user interface

- Comprehensive operation capability for all input and output data from each subsystem

- Safety mode that provides information on all safety measures taken into account to ensure proper station operation

- Maintenance mode that allows remote access to the system for carrying out preventive or corrective actions.